|

|

|

| QUALITY |

| |

|

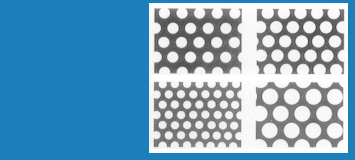

Our Quality Assurance team ensures that, at every stage of production, thecustomer’s specified requirements are being adhered to. Using digital measuring and logging equipment, our team can monitor entire production runs to ensure every that singledimension conforms to our customer requirements.

The strategic layout of our factory and its various component manufacturing stages facilitates the production process, allowing us to set new standards in perforated metal manufacturing.From material to process specification, we evaluate our clients’ products and make recommendations for the most cost-effective method of production.Live planning and scheduling data is used to manage and schedule resources allowing dynamic control of manufacturing output. Accurate and up-to-date production information provides feedback to all company departments and end customers.

Our commitment to the on-going education, training and development of our Human Resources ensures high process capability is achieved. This programme of training, technical and continual improvement is recognised in our quality accreditation to ISO 9001:2008. Internally, our organisation meticulously follows the process of Total Quality Management. |

| |

| |

|